This way we make it visible

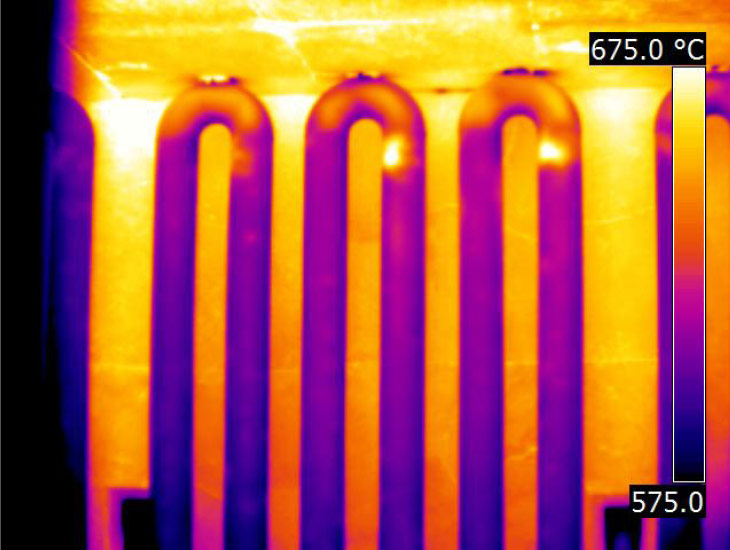

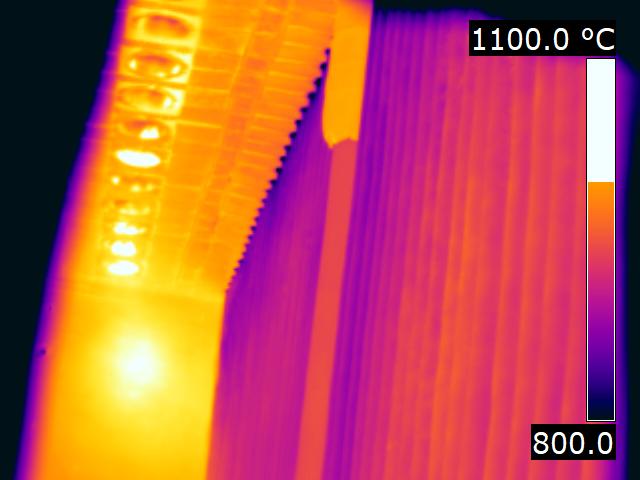

Thermal pattern indicating coking

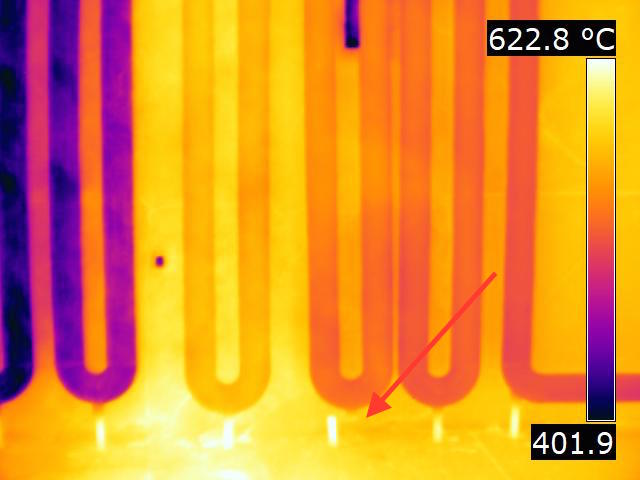

Loose tube support

Burner control and flame impingement

The findings

If we notice anomalities during the survey, these will be reported immediately. The images can be analyzed on the spot together with the customer.

There can also be written reports where you can choose between:

What are the costs?

Survey with a FLIR GF309 camera and lens extender from € 1.595,- a day.

What does it yield?

Insight into the state of your furnace so that you can prevent unscheduled stops. With the data you can optimize productivity and guarantee safety.

Our thermographers

We only work with certified (level 2 or 3) thermographers with a process technological background and extensive experience in furnace surveys.

Our equipment

We work with a FLIR GF309 IR camera with lens extender and changeable lenses (normal and telelens). We can see more tubes and see more detail than any other company.

Customers who have experienced the power of thermographic furnace survey